Our equipment

-

3D processor

-

2000t press

-

3D CAD

Main equipment

Click underlined parts and you can see pictures.

Machine factory

| Name | Maker | Number | Spec | |

|---|---|---|---|---|

| 3D processor | MVR48/59D | MHI | 1 | 8000X5900×3050H AT 5° |

| MPC36100B | TOSHIBA MACHINE | 1 | 10500X4400X3150H AT 5° | |

| MVR32/34 | MHI | 1 | 11600×4000×2250H AT90° | |

| MVR30/32 | 〃 | 1 | 6200×3200×1650H AT5° | |

| MVB27/18 | 〃 | 1 | 6000×2760×1350H AT90° | |

| MVB24/15 | 〃 | 1 | 4200×2400×1350H AT90° | |

| Side boring machine | MAFRS150B | 〃 | 1 | 11000(8400)×3000×1500(R/T)×900 X(6500+1900) ATC |

| MAFRS150B | 〃 | 1 | 16000(11815)×3000×1000(R/T)×900 X(+3275-8540) ATC | |

| KBT11WDX・A | KURAKI | 1 | 2000×1500×1450(R/T)×650 ATC | |

| KBT13FDX・A | 〃 | 1 | 3000×1700×1600×650 ATC | |

| Turningn centre | TMS1-32/70N | O-M Ltd. | 1 | φ7000×3000Z ATC |

| TMS2-20/40 | 〃 | 1 | φ4000×2700Z | |

| TM2-16N | 〃 | 1 | φ2000×1600Z ATC | |

| Drilling machine | DR-2000 | OHKUMA | 1 | 2000*1900 |

| DR-3000 | OHKUMA | 1 | 3000*2200 | |

| Engine lathe | MAZAKU-34 | YAMAZAKI | 1 | φ870*1500L |

| Presetter | KURODA | 1 | ||

| Overhead traveling crane |

1 | 50/15t | ||

| 5 | 30/15t、30/10t | |||

Programming room

| Name | Maker | Number | Spec |

|---|---|---|---|

| CAD/CAM | Mastercam | 1 | |

| Softech | 1 |

Plate factory

| Name | Maker | Number | Spec |

|---|---|---|---|

| Crank press | 1 | 200t | |

| Pipe beveling machine | Sanriku | 1 | 500A |

| Pipe bender | 1 | 2 | |

| Welding positioner | 1 | 2t | |

| Bending roller | Kanzaki | 1 | 25mmx3200 |

| Unit worker | Takeda | 1 | UW-45A |

| Facing machine | HATARI | 1 | 1550X1550 |

| Rotary planer | Daido | 1 | 3000X8000 |

| Sawing machine | Nicotech | 1 | SCH-25FA |

| Sawing machine | Amada | 1 | H-750HD |

| Sawing machine | Amada | 2 | H-650HD |

| Manipulator | Universal | 1 | 3000X4000 |

| Radial drilling machine | OOYA | 1 | RE3-2500 |

| Shot blast | Sinto | 1 | 250X250X250 |

| NC gas / Plasma cutting machine | KOIKE SANSO | 1 | TECHNOGRAPH-DXI(4500)G/P |

| NC cutting machine | TANAKA | 1 | KT-570V |

| Automatic beveling machine | SHINX | 1 | VX-1500 |

| Hydraulic press | Fukui | 1 | 2000t |

| Turning roller | 10 | 30t、20t、10t、5t | |

| Overhead traveling crane | 2 | 30t | |

| Overhead traveling crane | 12 | 10t.5t.2.8t | |

| Goliath crane | 9 | 10t.5t.2.8t | |

| Welding positioner | 3 | 3t、1t、0.5t | |

| CO2 welding machine | Pana, DAIHEN | 51 | 350A,500A,600A |

| TIG welding machine | Pana, DAIHEN | 7 | 350A,500A(AC/DC) |

| Arc stud welding machine | DAIHEN | 2 | MRN-1200 |

| Air plasma | DAIHEN | 7 | A-50,A-60,A-70,A-80 |

| Digital camera 3D instrumentation system | Yokogawa | 1 |

The third factory

| Name | Maker | Number | Spec |

|---|---|---|---|

| Goliath crane・Overhead traveling crane | 11 | 10t.5t.2.8t |

Sayo factory

| Name | Maker | Number | Spec |

|---|---|---|---|

| FABB-DECK production line | 1 | ||

| Overhead traveling crane | 5 | 4.8t、2.8t |

Headquarters Quality Assurance Department

| Name | Maker | Number | Spec |

|---|---|---|---|

| Hydraulic machinery | 3 | 200kg/c㎡。100kg/c㎡ | |

| Equipment for detecting metal fatigue | |||

| Ultra supersonic FD410S | 1 | ||

| Flaw detector | 1 | ||

| CAD/CAM | SolidWorks | 1 | |

| 3D printer | 1 |

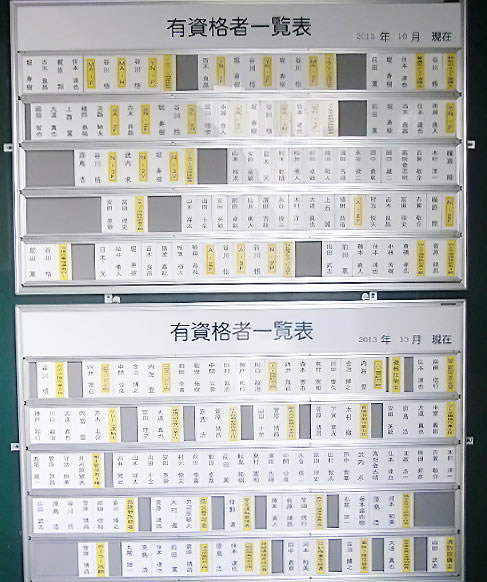

Accredited qualifications

- Manufacturing license for Class-1 pressure vessels. / DOL

- Manufacturing license for Class-1 pressure vessels. / ABS BV

- Manufacturing license for Class-2 pressure vessels. / NK LRS ABS BV

- Manufacturing JIS pressure vessels.

- Manufacturing plant for FABB-DECK